- The first autonomous production farm in the US started selling produce

- Seedo opens the world’s first fully automated cannabis farm

- ecoRobotix unveils an autonomous robot weeder

- MIT researchers use machine learning to enhance the flavour of basil

- A UK farm allows its cows to choose when they want to be milked

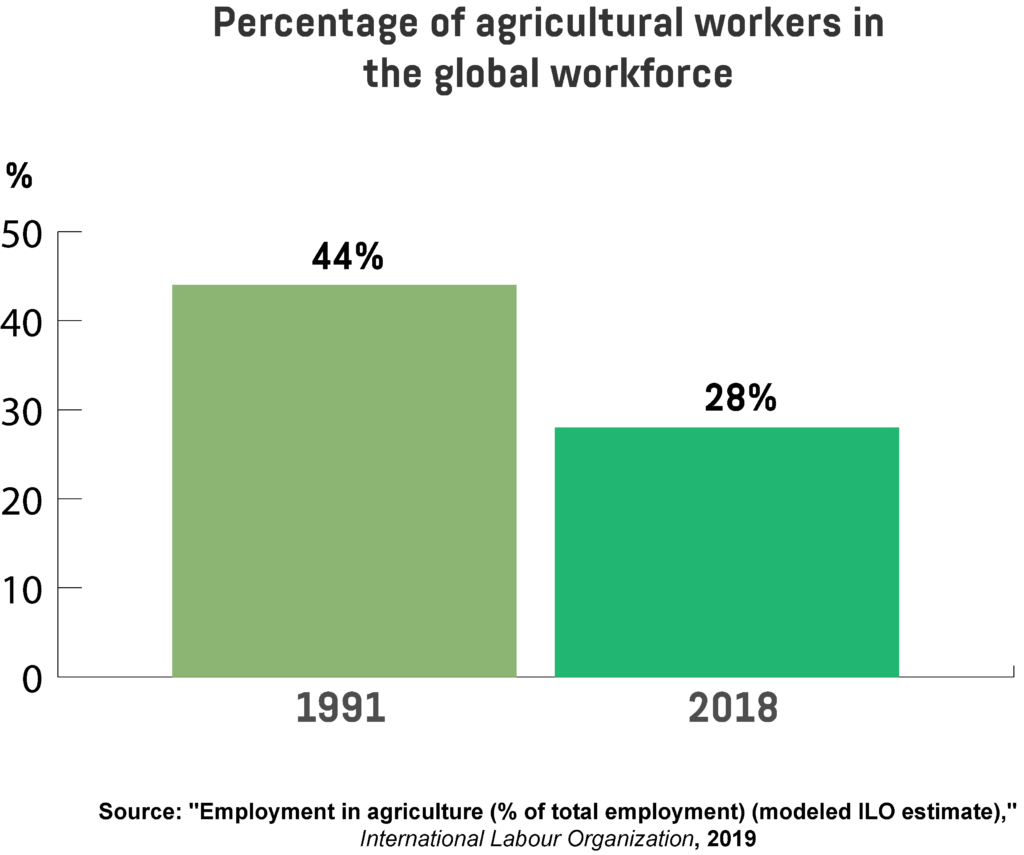

As the world’s population continues to grow, it’s putting more and more pressure on the agricultural industry to produce enough food to meet the increasing demand. However, this is more difficult to achieve than it sounds, particularly in the light of the growing shortage of farm workers. The International Labour Organization (ILO) estimates that the percentage of agricultural labourers in the global workforce declined from 44 per cent in 1991 to just 28 per cent in 2018. Farm work is very difficult, and young people are increasingly turning away from this profession towards other, more attractive options.

Furthermore, while the majority of the world’s population now lives in cities, most farms are located in rural areas, far away from consumers. Last but not least, there are also the costs and greenhouse gas emissions associated with transporting produce over large distances.

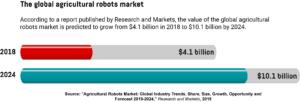

To address some of these issues, the agriculture industry is increasingly turning to robotics and automation. Robots have a wide variety of applications in agriculture today, including aerial data collection, field mapping, seeding, planting, fertilising, irrigation, harvesting, picking, intercultural operations, milking, and shepherding. According to a recent report published by Research and Markets, the value of the global agricultural robots market is predicted to grow from $4.1 billion in 2018 to $10.1 billion by 2024.

The first autonomous production farm in the US started selling produce

In October 2018, the robotic farming startup Iron Ox opened the first autonomous production farm in the United States. Located in a former commercial warehouse in San Carlos, California, the farm spreads over 743 square metres of space, and it can produce around 26,000 heads of lettuce, leafy greens, and herbs per year in hydroponic vats. That’s about 30 times more than a regular outdoor farm of a similar size can grow in a year.

Compared to traditional farming, hydroponic systems have a number of advantages: they use 90 per cent less water, require less space, and are completely sterile. Furthermore, their smaller physical footprint means they can be located closer to customers, reducing transportation costs and environmental impact. However, hydroponics still require manual labour. One of the most important tasks in this kind of farming involves transferring plants from one hydroponic vat to another as they grow, which is precisely what Iron Ox has been trying to automate.

The entire operation revolves around two robots developed by the company. The first one is called Angus, a 450-kilogram wheeled bot that has the task of transporting pallets of seedlings around the warehouse in their hydroponic growing vats. The second robot, or a robotic arm to be more precise, doesn’t have a name yet, but it does have an equally important task: picking up individual plants and moving them from one vat to another. A computer program nicknamed the Brain oversees the whole process, monitoring the growing conditions in pallets and adjusting the balance of gases and nutrients within them to create optimal growing conditions.

https://www.youtube.com/watch?v=2yETQVizpR0

However, even though Iron Ox refers to the farm as autonomous, humans are still an important part of its daily operations and perform tasks such as planting the seedlings and packaging the finished product. The plan is to eventually automate these tasks as well and make the farm fully autonomous.

The robot farm recently started selling its produce at the San Carlos branch of Bianchini’s Market grocery store. Customers can choose from three varieties of leafy greens, including Genovese basil, red-veined sorrel, and baby head lettuce, with prices ranging from $2.49 for the red-veined sorrel to $4.99 for four heads of baby lettuce. The prices are similar to other produce sold at Bianchini’s, but they’re a bit steep compared to those at Walmart, for example.

Seedo opens the world’s first fully automated cannabis farm

The Israel-based cannabis farming startup Seedo recently partnered with the northern Israeli kibbutz Dan to open the world’s first fully automated commercial cannabis farm. “We are entering a new era of growing where demand for pesticide-free products will only continue to increase,” says Seedo’s CEO, Zohar Levy. “We’re thrilled to partner with Kibbutz Dan to provide a business model with governments that the world can look to. We’ve built our commercial-scale system to reflect our philosophy that technology can provide precise and reliable results without sacrificing yield.”

Frequent use of pesticides and solvents in cannabis farming today presents a major health risk for consumers around the world, but especially those who use cannabis to treat illnesses. To address this issue, Seedo developed high-tech containers that allow cannabis farmers to control the purity of their crops and deliver a pesticide-free product that meets all of the compositional standards set by pharmaceutical and beverage companies.

Originally developed for home growers, each container features maximum daylight illumination, automated air conditioning, built-in carbon filters, and a smart post-harvest drying system. The physical aspects of cultivation are taken care of by robotic arms, while machine learning software makes sure that the growing conditions are optimal. The entire operation is overseen by a system of cameras. Each container can produce a minimum of 148 kilograms of dry cannabis buds per year. Early estimates suggest that the project will produce at least 14 tons of dry cannabis bud and generate $24 million in revenue within the first three years. Best of all, the containers won’t have to be used only to grow cannabis, as Seedo hopes the technology will allow them to determine the optimal growing conditions for other types of plant species as well.

ecoRobotix unveils an autonomous robot weeder

In today’s farming, crop dusting planes are often used to release herbicide over fields to fight weeds. However, while it’s undoubtedly fast, this approach also has several drawbacks. Most notably, it uses far more herbicide than necessary, which may explain the $26 billion spent on herbicide every year. Furthermore, as the planes spray herbicide over every crop in the field indiscriminately, not just weeds, farmers are forced to increasingly use genetically modified (GM) crops with built-in herbicide tolerance. To make matters worse, weeds develop resistance to herbicides over time, forcing farmers to use even larger quantities. But that may be about to change, thanks to a Switzerland-based robotics startup called ecoRobotix.

The company recently unveiled an autonomous robot weeder that has the potential to transform the industry and forever change how farmers fight weeds. According to ecoRobotix, the robot uses 90 per cent less herbicide and is 30 per cent cheaper than standard treatments. It uses an overhead camera, GPS, and sensors to navigate between rows of crops in a field. The camera also allows it to distinguish between different crops and detect weeds. Once detected, the robot uses two robotic arms to target the weeds directly and spray them with a small dose of herbicide. The company claims that it can detect and destroy more than 85 per cent of weeds. The robot is powered by two photovoltaic panels, allowing it to operate for 12 hours straight. While completely autonomous, it can also be controlled and configured via a smartphone app.

MIT researchers use machine learning to enhance the flavour of basil

Researchers at the MIT Media Lab’s Open Agriculture Initiative recently announced they were able to enhance the flavour of basil plants by using a combination of botany, chemistry, and machine learning technology. Rather than using genetic modification, which remains highly controversial, MIT researchers used computer algorithms to determine the optimal growing conditions that would produce the maximum concentration of flavour molecules, known as volatile compounds. To achieve that, the researchers modified shipping containers to be able to carefully control the environmental conditions within, including light, temperature, and humidity.

The basil plants were then placed in the containers and exposed to different sets of conditions, with varied light duration and exposure to ultraviolet light. The researchers then evaluated the taste of fully-grown plants by using gas chromatography and mass spectrometry, traditional analytical chemistry techniques, to measure the concentration of volatile compounds found in the leaves. These molecules are also known to contain valuable nutrients and antioxidants, which means that enhanced flavour could potentially offer health benefits as well. Finally, the researchers fed all of the data gathered by the experiments into machine learning algorithms, which evaluated millions of possible combinations of light and UV duration to determine the optimal growing conditions that would produce the best flavour. This, surprisingly, turned out to be 24-hour exposure to daylight.

In the future, the researchers hope they will also be able to enhance the healing properties of herbs by boosting the levels of certain compounds, while also helping farmers better adapt to climate change. “Our goal is to design open-source technology at the intersection of data acquisition, sensing, and machine learning, and apply it to agricultural research in a way that hasn’t been done before,” says Caleb Harper, a principal research scientist at MIT’s Media Lab and director of the OpenAg group. “We’re really interested in building networked tools that can take a plant’s experience, its phenotype, the set of stresses it encounters, and its genetics, and digitize that to allow us to understand the plant-environment interaction.”

A UK farm allows its cows to choose when they want to be milked

As part of a test of Cisco’s 5G infrastructure, a dairy farm in Shepton Mallet, England, has equipped 50 of its cows, approximately one third of the herd, with 5G-connected smart collars and health-monitoring ear tags. The collars allow cows to control the robotic milking system used at the farm. Rather than waiting for farmers to milk them, the cows can approach the system on their own once they feel ready, and the gates will open automatically to let them in. The collars also enable the system to recognise each individual cow and latch precisely onto its teats for milking, while the animal enjoys its food.

The collars and health-monitoring tags don’t cause the cows any pain or discomfort, and represent just a small portion of technologies already employed at this farm. These include sensor-operated curtains that open depending on the weather, automated brushes that rotate when the cows rub up against them, and a smart feeding system that automatically delivers food to the barn through rails mounted on the ceiling. “We can connect every cow, we can connect every animal on this farm,” says Cisco’s Nick Chrissos. “That’s what 5G can do for farming — really unleash the power that we have within this farm, everywhere around the UK and everywhere around the world.”

Robotics and automation have found a wide variety of applications in the agricultural industry in recent years, helping farmers address some of their most pressing issues, such as a growing shortage of labourers and the increased demand for food. From robotic arms that transfer individual plants between hydroponic vats as they grow, to autonomous robot weeders, robots have become an increasingly common sight on farms around the world, decreasing their labour costs, improving efficiency, and boosting crop yields. It remains to be seen whether our farms will ever become fully automated, but it’s already clear that the technology will have a major impact on the future of agriculture.

Share via: