- London is using robots to get rid of ‘fatbergs’

- Robots and machine learning software identify defects and blockages in Washington’s sewer pipes

- India’s Bandicoot robot eliminates the need for manual scavenging

- This slithering robot can inspect chemical storage tanks

- Avidbots launched commercial floor cleaning robots

- How robots are taking on dirty jobs

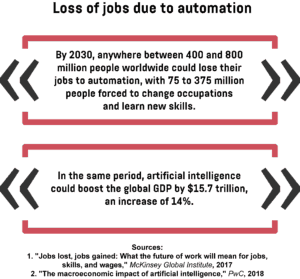

Thanks to rapid advances in artificial intelligence, machine learning, and robotics, our world is becoming increasingly automated, fundamentally changing the way we live and work. While growing automation has made our lives easier and more convenient, as well as helped companies increase productivity, it’s also brought concerns about the potential effects on the human workforce. The McKinsey Global Institute, a US-based think tank, estimates that anywhere between 400 and 800 million people worldwide could lose their jobs due to automation by 2030, with 75 to 375 million forced to change occupations and learn new skills.

While concerns about its impact on human workers remain, increased automation is expected to have a more favourable effect on the world’s economy. A recent report published by PricewaterhouseCoopers (PwC), a UK-based professional services firm, predicts that artificial intelligence technology could boost the global GDP by $15.7 trillion by 2030, a 14 per cent increase. The growth of the GDP will be driven by two major factors: increased productivity and higher consumer demand, resulting from the availability of AI-enhanced products and services.

There’s one area where the adoption of robots wasn’t met with resistance, though. As it turns out, people are more than happy to let robots do the dirty work for them. A recent survey of UK employees reveals that 83 per cent of respondents want robots to take over unhealthy jobs, while 77 per cent say the same about hazardous occupations. So, it’s not at all surprising to see companies around the world increasingly assigning these tasks to machines, keeping human workers safe from harm.

London is using robots to get rid of ‘fatbergs’

A ‘fatberg’ is a large mass made of fat, grease, wet wipes, and other non-biodegradable toiletry items that forms in the sewers over time. In recent years, these underground monstrosities have become a major problem for London, a result of its reliance on ageing Victorian sewers and a growing population. Thames Water, the UK’s largest water and wastewater company, decided to approach this issue with an innovative solution – an army of sewer-scrubbing robots.

The company recently introduced pipe-crawling robots equipped with ultra-high-pressure water jets made by a Dutch company called Sewer Robotics. The robots are controlled remotely by a human operator, who uses the on-board camera to guide the machines through the sewers, locate the fatbergs, and direct the cleansing fluid. The water jets are capable of producing pressure of up to 40,000 psi, which is strong enough to cut through concrete and clear fatbergs with ease.

However, that’s not the only tech gadget currently employed by Thames Water. The company also adopted an acoustic sensing device called SewerBatt, which can be used to inspect the condition of sewer pipes. Once lowered into a pipe, the device emits a 10-second burst of sound and then picks up the returning signal with a microphone. The signal is then analysed by the software to determine the diameter and length of the pipe and whether there are any obstacles.

Robots and machine learning software identify defects and blockages in Washington’s sewer pipes

DC Water, Washington DC’s metropolitan water and sewer authority, is another company that’s relying on robotic technology to monitor the condition of sewer pipes. Developed by a Pittsburgh-based robotics company called RedZone, the robots can crawl autonomously through pipes of various diameters, capturing video footage of their surroundings. The footage is then analysed by software called Pipe Sleuth, which uses machine learning to identify and classify defects in the pipe network. Once the analysis is complete, the software generates a report that specifies the type, location, and severity of each identified defect. The report can then be reviewed by a human employee, who can manually edit the results if they spot any mistakes, helping the software learn and improve the accuracy of future scans.

According to Thomas Kuczynski, the vice president for information technology at DC Water, Pipe Sleuth can identify 46 different problems, including blockages, fat and grease build-up, invasive plants, deformities, cracks, breaks, and dislocated pipes. The software is 90-95 per cent accurate in hardened clay pipes, while materials like concrete and plastic present more of a challenge, due to differences in reflections that make it difficult to identify things like blobs of grease. Kuczynski claims that the camera-quipped robots can cover about eight kilometres of pipes per day, which is three times more than with traditional camera surveying methods. Combined with Pipe Sleuth’s abilities, which can analyse half an hour of footage in just three minutes, this could help the company reduce the cost of sewer inspection by up to 75 per cent, revolutionising the way water utilities inspect sewer pipes and prioritise repairs.

India’s Bandicoot robot eliminates the need for manual scavenging

Manual scavenging is a serious problem in India. Even though the practice has been banned by the government, it’s still common for human scavengers to enter and clean manholes manually. Unfortunately, working in such a risky environment filled with harmful gases and toxic fluids can lead to a variety of health issues and even death. Despite the risks, underprivileged citizens are often forced to take these jobs due to a lack of proper education and job opportunities, as well as a lack of proper technological solutions that would be able to take their place. To address these issues, the Indian robotics firm Genrobotic Innovations developed a robotic system for manhole and sewer line cleaning called Bandicoot.

Developed in collaboration with the Kerala Startup Mission and the Kerala Water Authority, Bandicoot was officially deployed for the first time in February 2018. The robot consists of two separate parts: a robotic unit with an arm and four legs that goes inside the manhole and takes over the cleaning operation, and a control panel unit outside the manhole that allows a human operator to monitor and control Bandicoot. The robotic unit is equipped with a waterproof night-vision camera that transmits a 4K video feed in real time, while various sensors allow it to measure manhole dimensions, material and chemicals inside the manhole, humidity, temperature, and other environmental parameters. There’s also an 18-litre bucket unit that enables the robot to collect waste.

Bandicoot can operate in two modes: automatic and semi-automatic. In automatic cleaning mode, which is suitable for standard manholes, the robotic unit goes inside the manhole and navigates and cleans on its own using AI programs based on data gathered by sensors. However, when the robot encounters a non-standard manhole, a human operator assumes control through the control panel. To minimise potential damage upon exposure to toxic gases and fluids, the robot is made of resilient carbon nano-fibre, has only a few electronic parts, uses pneumatics, and it’s waterproof. Bandicoot is very easy to use and can be operated by just about anyone after just one week of training.

This slithering robot can inspect chemical storage tanks

Inspecting chemical storage tanks is an incredibly dirty and complicated job. It’s also quite dangerous and requires a team of paramedics and an ambulance to be present when a person goes into a tank. However, thanks to Sarcos Robotics, that may soon be a thing of the past. The Salt Lake City-based company developed a 1.2-metre-long snake-like robot called Guardian S, which uses special magnetic tracks to slither along various surfaces, including smooth metal walls and slimy floors.

Using sensors embedded in its head and tail, the robot can inspect the tank and detect leaks, transmitting the data to human workers outside for analysis. It’s also capable of avoiding any type of debris that might be lying at the bottom of the tank, such as broken pieces of pipes, bolts, and hose sections. It can even rise up on its hind section like a cobra if it needs to get a better look at something and take a photo. Once it’s done, workers can simply wash it off with water. In addition to inspecting chemical storage tanks, Guardian S could also be used to inspect wind turbines for corrosion, rust, and metal fatigue, as well as oil and gas sites.

Avidbots launched commercial floor cleaning robots

You’d be hard-pressed to find anyone who considers floor cleaning to be an enjoyable activity, which is why most people would probably welcome the news that the Canadian robotics company Avidbots has developed an autonomous floor scrubbing robot called Neo. Designed for airports, malls, manufacturing sites, warehouses, and universities, Neo uses a combination of proprietary software, 3D sensors, and cameras to autonomously clean an environment. It can also connect to the cloud through WiFi and 4G, allowing for continuous monitoring and enabling the robot to receive over-the-air software updates with new functionalities. Before it gets down to business, Neo is taken on an initial walkthrough, in which it scans the layout and builds a map of the facility. This allows it to get to know its environment and adapt to any changes. For example, if it encounters a new obstacle that wasn’t there in the original scan, such as a temporary display or a booth, Neo will simply calculate a new route. When the obstacle is removed, it will revert to its original route.

The hospitality industry could also soon be able to enjoy the benefits of robotic technology. RLH Corporation, a US-based hospitality company, recently joined forces with Peanut Robotics to develop an automated housekeeping robot. Designed to work alongside a human housekeeper, the robot is capable of handling supplemental housekeeping tasks such as cleaning toilets and collecting linens, leaving human employees more time to focus on more important aspects of their job. The robot is equipped with a prehensile arm capable of holding tools. To make sure that it can’t harm anyone, the arm has a level of strength that’s lower than that of a human. While it can only handle some routine housekeeping tasks at this point, the company plans to add other functionalities in the future, including stocking minibars and carrying guest luggage.

How robots are taking on dirty jobs

Dirty jobs can be highly unsanitary and dangerous, exposing workers to numerous health hazards. However, as undesirable as they are, someone needs to do them, which is why companies around the world are increasingly turning these tasks over to robots in an attempt to increase productivity and protect human workers from harm. Whether they’re used to crawl through sewers to inspect the condition of pipes and fight fatbergs, inspect chemical storage tanks, or clean floors and toilets, machines are starting to replace humans in some of the world’s dirtiest occupations. While the growing adoption of robotic technology does raise some concerns about potential impacts on human workers, this development should be viewed in a positive light, as it allows humans to switch to less hazardous, more rewarding jobs instead.

Share via: