- NASA plans to use robots to turn Martian soil into rocket fuel

- Nanomaterials may help plants grow on Mars

- The Refabricator turns plastic waste into useful tools

- 3D printing skin, bone, and body parts to heal injured astronauts

- Is a Mars colony really the best way to save humanity?

From the first moment we looked up and realised there were other planets up there, humanity has dreamed about conquering space, the final frontier. In 1969, we set foot on the moon for the first time and we haven’t looked back since, launching several space stations into orbit and sending unmanned missions to a number of planets in our solar system and beyond. However, the next stage of that journey is bound to be the most challenging yet – establishing a human presence on Mars.

When Elon Musk founded SpaceX in 2002, he said it was because he wanted to give the human race a second chance. He didn’t believe that NASA could get us to Mars fast enough, leaving humanity in a precarious position, in which a single catastrophic event, such as an asteroid strike or nuclear war, could erase every trace of our existence from the universe.

To be self-sufficient and sustain human life indefinitely, a Mars colony would need to have access to a renewable source of water, oxygen, food, and power, among other things. So, is this something that could conceivably be done with the technology currently at our disposal?

NASA plans to use robots to turn Martian soil into rocket fuel

NASA engineers recently announced they’re working on a mining and chemical-synthesis plant that will be able to produce water, oxygen, and rocket fuel using only local resources found on the surface of Mars. Developed in a collaboration between several teams across NASA, the plant would be entirely operated by autonomous robots and would enable humans to one day live and work on the Red Planet. “Officially, it’s known as an in situ resource utilization (ISRU) system, but we like to call it a dust-to-thrust factory, because it turns simple dust into rocket fuel,” writes Kurt W. Leucht, a team leader at the Swamp Works Lab at NASA’s John F. Kennedy Space Center in Florida, one of the teams working on the project.

Before it’s sent to Mars, though, most of the equipment will first be tested on the lunar surface to make sure everything works properly. The Martian soil, also known as regolith, is believed to contain trace amounts of water. This discovery inspired NASA engineers to develop technology that would allow them to extract water from the regolith and then strip it into hydrogen and oxygen through electrolysis. The hydrogen would then be combined with carbon from the atmosphere to produce methane, which can be used as rocket fuel.

The first step involves excavating the regolith. For this purpose, NASA developed an autonomous mining vehicle called RASSOR, or Regolith Advanced Surface Systems Operations Robot. Equipped with two opposing bucket drums that spin in opposite directions while digging, the robotic excavator was designed specifically to operate in low-gravity conditions. Once excavated, the regolith is transported to a processing facility, where it’s deposited into an oven and heated until the water molecules are extracted from it and collected with a condensation tube.

The remaining regolith is then dumped on the ground and hauled away by the RASSOR to be used for 3D printing all sorts of objects and structures. The water, on the other hand, is purified using a multistage filtration system and several deionising beds. Besides being used for drinking, the water would also be used to produce rocket fuel. The H2O molecules are first split into hydrogen and oxygen molecules using an electrolyser, after which the gases are compressed and liquefied. Hydrogen is then combined with carbon from the Martian atmosphere to produce methane gas, thanks to a chemical process called the Sabatier reaction. So, this robotic factory would be able to deliver three different end-products necessary for life on Mars: water for drinking, oxygen for breathing, and methane for fuel.

Nanomaterials may help plants grow on Mars

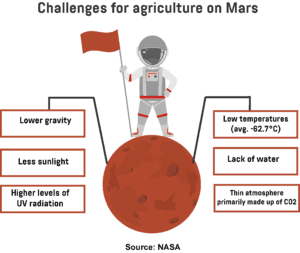

With water, oxygen, and fuel taken care of, the colonists would also need something to eat. Unfortunately, even though Mars is the most similar to Earth of all the planets in the Solar System, there are still a number of major differences that would prevent plants from growing there. In addition to having lower gravity than Earth, Mars also receives less sunlight and much higher levels of ultraviolet radiation. Combined with low surface temperatures, lack of water, and a very thin atmosphere primarily made of carbon dioxide, it makes Mars a very inhospitable environment. Terraforming Mars has been touted as a potential solution to this problem for a while now. However, not only would that process be extremely long, maybe even thousands of years, but scientists aren’t even sure whether it can be done at all. Luckily, there may be another way thanks to nanotechnology.

Researchers from the University of Melbourne recently announced they were able to augment plants with nanomaterials to give them new abilities, such as harvesting sunlight more efficiently, which may one day allow them to thrive on Mars. For years, scientists have been modifying plants with foreign materials thanks to their extensive vascular networks. While these allow them to easily absorb water and molecules dissolved in fluids, that’s not the case with nanomaterials like metal-organic frameworks (MOFs), which are just too large to penetrate roots. However, the Australian researchers managed to get around this problem by feeding plants MOF precursors, which they were able to absorb and later convert into finished nanomaterials.

To make this possible, the researchers first mixed metal salts and organic linkers with water, after which they placed plants into the solution. The plants were then able to transport these precursors into their tissues and use them to grow two different types of fluorescent MOF crystals. These MOFs could then be applied to plants as a form of coating to help them convert harmful ultraviolet (UV) rays into light they can use for photosynthesis. “As we contemplate growing crops in space or on Mars where you don’t have an atmosphere and are bombarded by UV rays, something like this could be helpful,” says Joseph Richardson, the project’s lead researcher. “That’s because it not only protects the plants from the UV rays, but it also turns them into useful energy. Especially as you get farther away from the sun, it’s harder to capture all of the light you’d need for photosynthesis.”

The Refabricator turns plastic waste into useful tools

In addition to water, food, and oxygen, future colonists will also need all kinds of supplies and equipment to survive the Red Planet’s harsh environment. And that’s where 3D printing technology comes in. The Refabricator is a new gadget developed by the tech company Tethers Unlimited that combines a 3D printer and plastics recycler in a single machine. Delivered to the International Space Station (ISS) during a recent resupply mission, the Refabricator can melt down waste plastics and turn it into useful tools for astronauts. Once an astronaut places a piece of plastic they no longer need into the machine, it proceeds to melt it down into a 3D printing filament, which is then used to 3D print new tools.

While the Refabricator will undoubtedly come in handy for people aboard the ISS, that’s not where its real value lies. This technology has the potential to revolutionise space exploration and bring us one step closer to a self-sustaining Mars colony. The colonists would no longer need to bring everything along with them when they set off for Mars. Instead, they could just bring a few things necessary to start the colony and then recycle them once they’re no longer needed and turn them into the things they need for the task at hand. “The Refabricator demonstration is a key advance toward our vision of implementing a truly sustainable, in-space manufacturing ecosystem,” says Rob Hoyt, the CEO of Tethers Unlimited. “Astronauts could use this technology to manufacture and recycle food-safe utensils, and turn what is now inconvenient waste into feedstock to help build the next generation of space systems. We believe re-using [sic] the waste could reduce the cost and risks for NASA and private space exploration missions.”

Recent research published by NASA in the The International Journal of Advanced Manufacturing Technology reveals that 3D printers work normally in space, producing objects that perform just as well as their Earth-made counterparts. The research is a culmination of a four-year-long experiment in which NASA engineers used 3D printers to produce tools and other objects on Earth, in simulated microgravity, and on board the ISS, in zero-G. While there were certain discrepancies between the objects, scientists believe these were due to changes in the manufacturing process settings and not the influence of gravity or microgravity, with all objects displaying similar layer thickness, layer adhesion, relative strength, and relative flexibility.

3D printing skin, bone, and body parts to heal injured astronauts

The applications of 3D printing technology in space could extend far beyond producing tools and other objects needed for extraterrestrial missions. The technology may one day also enable us to 3D print skin, bone, and body parts to treat injured astronauts. The European Space Agency (ESA) recently gathered the foremost experts in 3D bioprinting and regenerative medicine for a two-day workshop at the European Space Research and Technology Centre (ESTEC) in the Netherlands, which aimed to explore the viability of using 3D bioprinting to produce biomaterials such as skin tissue or even entire organs in space. Unlike standard 3D printers, which use plastics or metals to create 3D objects, 3D bioprinters rely on special ‘bio-ink’ based on human cells to produce tissues. This technology has already been used recently to bioprint ligaments and tendons from stem cells and to 3D print scaffolding in regenerative medicine.

“We’re asking what astronauts would need in the short, medium and long term, and what steps are needed to mature 3D bioprinting to a level where it can be useful in space. We’re defining a development roadmap and timeline, with the aim that this group becomes a scientific working group in [the] future, pushing progress on,” says Tommaso Ghidini, the head of ESA’s Structures, Mechanisms and Materials Division. Any future colony on Mars is bound to experience medical emergencies eventually. As they won’t be able to count on help arriving from Earth, the colonists will have to find a way to treat any potential injury or disease on their own. “In the event of a medical emergency a rapid return home will not be feasible. Instead, patients will have to be treated on the spot. Thus we are evaluating the feasibility and added value of implementing different 3D printing technologies and bioprinted tissues into future exploration missions,” adds Sandra Podhajsky from OHB System’s Life Sciences Group, who is managing this project.

The colonists will also need to overcome the issue of performing surgery in outer space, where access to equipment and personnel will be extremely limited. “The surgery required to transplant printed tissues also requires a rethink. The sterile environment, equipment and trained personnel of a terrestrial operating theatre may not be available, as well as the single-use surgical items employed casually on the ground,” says Prof. Michael Gelinsky, the head of the Center for Translational Bone, Joint and Soft Tissue Research at the University Hospital of the Dresden Technical University. Robotic surgeons have been proposed as a potential solution to this problem. However, as the communications delay between the Earth and Mars will make telemedicine impossible, the robots would have to be equipped with artificial intelligence that would enable them to operate autonomously.

Is a Mars colony really the best way to save humanity?

However, not everyone agrees that a colony on Mars should be our top priority at this time, and that we should be focusing our attention closer to home instead. Some have gone so far as to accuse Musk of elitism, criticising him heavily for working on a solution that would only save the ‘chosen few’, while leaving the rest of humanity to perish. “I think that’s a dangerous delusion because Mars will be a more hostile environment than the top of Everest or the South Pole, and dealing with climate change here on Earth is far more important than terraforming Mars,” says Martin Rees, a cosmologist at Cambridge University. While he doesn’t oppose the idea of private companies exploring space, Rees is convinced that there are other ways to save humanity and that the money would be better spent elsewhere.

Even in the event of a nuclear disaster or a natural catastrophe, the Earth would probably remain far more hospitable to human life than Mars. Scientists estimate that even if we caused a nuclear winter, which is the absolute worst-case scenario, the surface temperatures on Earth would fall by about 9 to 11 degrees Celsius at most. The average temperature on Mars, in comparison, is minus 60 degrees Celsius. In fact, some have suggested that there isn’t a single scenario in which a colony on Mars would be a better solution than a bunker in New Zealand, for example.

The colonisation of space is one of the most challenging endeavours humanity has ever undertaken. Initially dismissed as pure science fiction, this dream has been steadily moving closer to reality. However, there’s still a lot of work left to be done for us to get there. We’ll have to make significant advances in many different fields, including propulsion, life support, artificial intelligence, and medicine. It’s difficult to estimate at this point how long it will take us or whether it can even be done at all, but it’s a goal worth striving for. The future of humanity may depend on it.

Share via: