- 4D printing – from code to smart, morphing objects inspired by nature

- Shape-shifting clothing, bikinis and shoes

- 4D printing technology to maintain superiority on the battlefield

- Smart cities with self-assembling homes

- The creation of live, active, adaptive tissue

- Programming matter – legal and criminal challenges

3D printing is also known as additive manufacturing and celebrates its 30th birthday this year. Yes, it has been around for quite some time and it has already made its way into many aspects of our lives. The technology is used in the corporate manufacturing industry to produce toys, tools, household appliances and many other things you can think of. Other areas of application include the automotive industry, aerospace, electronics, construction. Even the medical industry benefits from this technology to create hearing aids, prostheses and even new human tissue. 3D printing is at the core of many research initiatives, from recreating burn-victims’ facial features to the printing of food. Revolutionary and incredible, yes. But wait until you read about 4D printing upping the ante.

If you incorporate ‘shape-memory’ polymer fibers into a composite material, you can use a 3D printer to manufacture an object that transforms into a different shape as soon as it is exposed to certain temperatures or moisture levels. What developers are essentially trying to create with this technology is robot-less robotics; materials that have the ability to transform after being exposed to energy – without the use of electronics and circuit boards.

4D printing – from code to smart, morphing objects inspired by nature

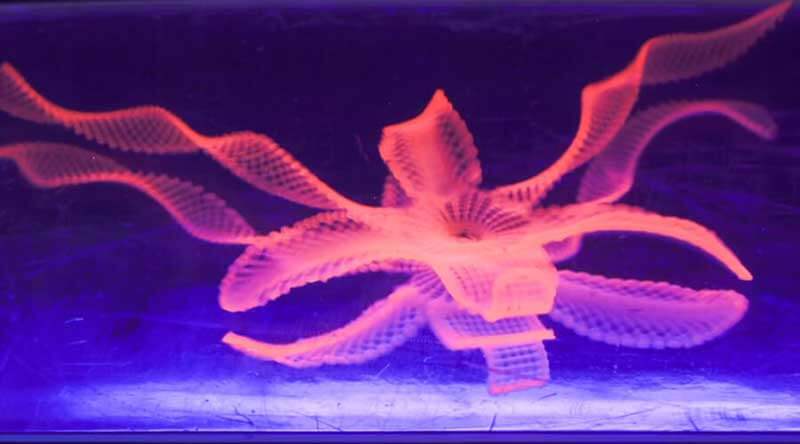

While 4D printing is achieving attention outside of the labs, to many, the concept is still very foreign. Basically, 4D printing draws inspiration from nature’s the ability to alter shape, self-repair and self-replicate in response to external environmental conditions such as sunlight, moisture or temperature.

4D printing uses flat printed items that are made from gel-like smart materials developed to the level of nano-composites. These items are then enhanced with the dimension of time and memory – enabling them to change shape with atmospheric and sensory changes. This is possible because these smart materials are pre-programmed with code. This code determines the direction, the number of times as well as the angles at which the composite material is able to curl, bend, expand, twist, flex or shrink. The extent to which the material is able to shape-shift also depends on the location and orientation of the fibres within the composite materials.

The greatest innovation in 4D printing technology is that smart materials have the incredible ability to incorporate the pre-programmed information they need to assemble themselves. This enables the materials to learn how to respond dynamically to their surroundings. 4D printing could change the world, in fact, it is already doing so. Many interesting scientific techniques have already been developed to produce shape shifting structures, even live tissue. Industries that can especially benefit from the use of the adaptive, composite materials used in 4D printing include packaging, manufacturing and even biomedical. Material for clothing, tyres and shoes could be programmed to respond to weather conditions by changing their permeability or their grip. Cars could be programmed to automatically increase or decrease speed by modifying their aerodynamic components. Furniture could be printed to auto-assemble. The potential applications are as incredible as they are endless.

Shape-shifting clothing, bikinis and shoes

‘Smart clothing’ could soon get an entirely different meaning. Up until recently, 3D printers were only able to print rigid objects. Early attempts at printing clothing have resulted in ‘wearable art’ rather than genuine wearable garments. One way of overcoming the rigidity of 3D printed materials was by decreasing the size of the plastic parts and assembling them by hand. One example is the N12 3D printed bikini by Continuum Fashion which features thousands of small circles, joined together by tiny links. 4D printing technology takes this a step further. A project called the Kinematics Dress by Nervous System saw the creation of a 4D printed dress with the ability to move like real fabric by adapting to the changing movements of the wearer’s body. This was made possible through minuscule printed hinges which are actually part of the design of the dress but played a crucial role as well. Because the printer was smaller than the dress to be printed, the designer had to come up with a solution. In order for the dress to fit inside the machine for fabrication, Creative Director of Nervous System, Jessica Rosenkrantz, used a physics simulation to make the dress smaller by ‘hinging’ it and folding it up. After printing, the hinged design required no assembly and magically folded out into a finished dress. 4D programming has also been tested for the development of smart shoes that are able to adapt to external conditions such as movement, impact, temperature and atmospheric pressure. Imagine your hiking boots morphing into running or basketball shoes!

4D printing technology to maintain superiority on the battlefield

The US military invests in many up and coming innovations such as invisibility and camouflage technologies as well as nanotechnology to develop ways to conceal people and objects from the human eye and microwaves. It then comes as no surprise that, in keeping with the military’s quest to remain technologically superior on the battlefield, they have also expressed an interest in 4D printing technology. 4D printing could maximise the features and functionalities of other technological developments. 3D printed uniforms enhanced with 4D intelligence could adapt in such a way that it could protect soldiers from the extreme hot or cold temperatures or morph into colours that provide optimum camouflage, depending on their location. Also, 4D enhanced printed metal could improve their trucks’ or vehicles’ performance by adapting to specific conditions in the environment.

Smart cities with self-assembling homes

We apply increasingly sophisticated methods when it comes to building our cities and their structures. The materials we use are however static and require the assistance of people and machinery to get them into their final, intended shape. With 4D printing technology, we could develop lighter, more resilient structures that are able to adapt to changing requirements. Entire buildings could be 4D printed, arrive flat-packed and assemble themselves by exposing them to outside stimuli such as gravity, water, heat or light. Other potential applications of 4D printing would be water pipes that can adapt to changes in the ground by either contracting or expanding. And imagine self-healing potholes in our roads. Engineers and scientists all over the world are excited about the endless possibilities.

The creation of live, active, adaptive tissue

Advancements in 4D printing can make the creation of actively adaptive cells possible. For instance, an implanted 4D-printed organ would change according to the changes of and in the patient’s body. The possibilities that are emerging with the development of 4D printing technology are already shifting from the inorganic to the organic. Printing new ‘skin’ for skin grafts is among the many possible 4D printing applications in healthcare. Over time, 4D printed skin is able to freely change its shape, making it a promising application for burn victims. Other applications include medical implants. 4D printing technology makes it possible to generate shape-shifting forms as well as functionality without the need for external intervention. The aim is to print tissue that can survive inside the body for as long as the patient is alive. The science of bio-programmable matter and nanotechnology also introduces unprecedented solutions such as personalised medicine and smart pharmacology. Research projects such as ‘DNA origami’ show that nano-scale protein structures are able to create nano-robots which are specifically designed to locate and destroy cancerous cells inside a patient’s body.

Programming matter – legal and criminal challenges

The exponential developments in nanotechnology, material science and other technology have made programmable matter a real possibility. The benefits of 4D printing, such as adaptability, customisation and cost-savings are undisputed. There are however challenges and risks as well. The technology could fall into the wrong hands and used for harmful and criminal purposes. There are also concerns around patenting and intellectual property law – especially when it comes to reproduction. Then there’s the question of accountability and responsibility. Should a 4D printed item or parts thereof malfunction, who would be to blame? The developer of the smart material? The programmer, the manufacturer?

Share via: