- The supply chain is finding itself in the middle of a huge transformation

- It’s become an incredibly complex system of people, technologies and processes

- Those who don’t prepare to be part of this future will likely stay behind in the past

Every couple of years the business world witnesses new waves of change and disruption. This is true for various sectors, and the supply chain industry is no different. In fact, it’s finding itself right in the middle of a huge transformation. From the very first assembly lines to the advanced high-tech solutions we have today, the supply chain and logistics are continuously evolving and the latest trends focus on smart, technology-driven management, reducing operating costs and optimising efficiency. From self-learning stock-picking robots to delivery drones and IoT platforms that connect manufacturers with shippers and retailers in real-time, the future supply chain promises to be cleaner, faster, more agile and fully autonomous. How well a business can embrace the current and future disruptions in the supply chain and logistics determines its future.

Factors driving the next phase of transformation

Compared to how things are today, supply chain logistics management used to be pretty straight forward. Manufacturers sold to wholesalers or retailers and sales reps contacted their clients and wrote orders. Retailers either placed their orders by phone or by mail. This relatively simple supply chain faced extinction halfway through the nineties and transformed into a complex ecosystem of people, technologies and processes. Our current supply chain and logistics models are likely to experience the same fate and are expected to become obsolete by 2025, according to the US Roadmap for Materials Handling & Logistics. There are various factors that will drive the next phase of transformation, some of which are already well underway and others are in their early stages of development. They include robotics and automation, omnichannel and ecommerce, sensor technology and the Internet of Things, big data as well as supply chain visibility & collaboration. In this article, we will describe these disruptors in more detail.

1. Robotics

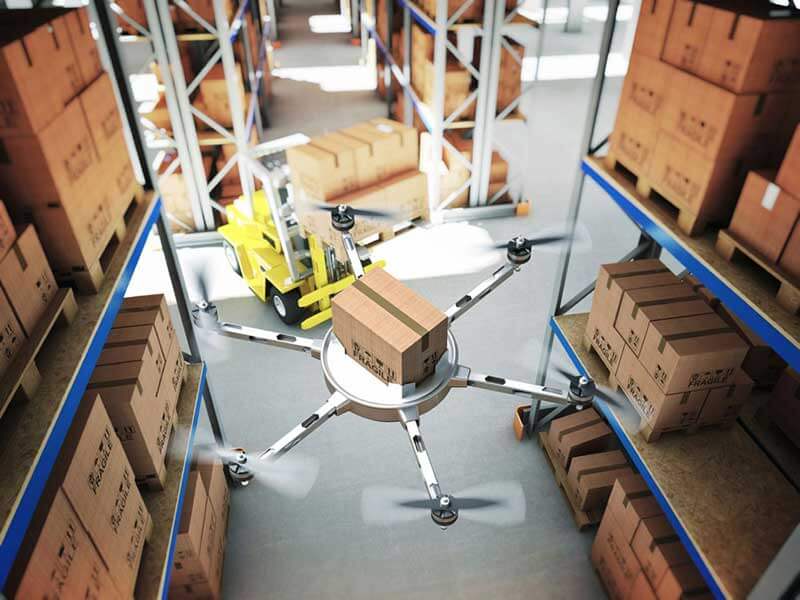

The integration of self-driving systems and wearable computing into coordinated systems will result in revolutionary changes in the supply chain industry. Unmanned cargo ships, autonomous trucks, self-learning stock-picking robots in warehouses and drones delivering groceries are fast becoming reality, significantly reducing the potential for human error. Robotics is playing a role in each and every part of the supply chain, from raw materials extraction all the way to ‘the last mile’ – the delivery to the customer.

A third of organisations already have some form of robotics in their supply chains. Within ten years, this will have expanded to three-fourths. The easiest ones to visualise are autonomous vehicles and drones. Drones can be deployed in manufacturing and fulfillment as well as for stock picking, pallet moving, maintenance, security and small parcel delivery. Two well-known companies that are looking at deploying drones are Amazon and Domino’s pizza.

Every element can be integrated: warehouse robots with embedded sensors can detect product quality and communicate this directly to planning systems, ultimately producing actionable insights to supply chain management. Integrating robot systems and machine learning algorithms, robot process automation can greatly increase efficiency and reduce costs. The adoption of robotics will depend as much on the resultant profits as on public perception, but minimising human error and improving efficiency is ultimately their main purpose.

After buying Kiva Systems, Amazon implemented the system in a number of their warehouses, considerably improving efficiency and increasing profits. The system consists of robots that autonomously move individual boxes or pallets around their warehouses. And it’s not just the large companies who have jumped onto the robotics bandwagon. Even small and medium-sized organisations have implemented robots such as the relatively cheap Baxter robot. This machine can work for thousands of hours without stopping. This would neither be possible nor affordable with human employees.

Smart, economical driverless trucks will be able to quickly and safely transport goods with operational costs being much lower than current, traditional trucks. Daimler believes that they will have fully automated trucks on the road within the next ten years.

2. Omnichannel and ecommerce

While 93 percent of sales are currently generated through brick-and-mortar stores, in five years’ time, they are predicted to account for just 81 percent. Surveys have indicated that omnichannel can have a compounding effect on growth. Customers who shop online as well as in-store spend twice as much as customers who only shop at brick-and-mortar stores.

When it comes to supply chain management, manufacturers, distributors, retailer and online merchants are currently stuck with old processes. Consumers now expect to be able to browse, buy and return products across different channels. To meet customer expectations and fulfill orders immediately, omnichannel and ecommerce require an accelerated movement of products through the entire supply chain and they need to be able to reach the customer beyond the brick-and-mortar store. This requires real-time visibility across the supply chain and a view of the customer as they navigate from one channel to another. This will require significant organisational transformation of supply chain responsiveness and agility, and companies will need to implement strong data and analytics capabilities to make this happen.

3. Sensors and the Internet of Things

The Internet of Things is supported by embedded sensors communicating in real-time, without any human intervention. The Internet of Things and sensor technology will play a critical part in the transformation of the logistics industry and warehouse processes. Surveys have indicated that processes like purchasing, order processing, transportation, production scheduling, inventory management and customer service already heavily rely on sensors and Internet applications. In manufacturing, sensors can spot problems and offer instructions for correction. In transportation, sensors can be embedded in parcels and transportation containers so that they can be monitored and tracked via GPS – improving routing and delivery. An impressive array of information can be collected from sensors in vehicles, such as real time operating values and – important for monitoring and maintaining the health of a vehicle and minimising downtime – temperature, velocity, vibration, acceleration, fluid levels, wear factors, tolerances etc. Sensor technology and the IoT enable organisations to monitor and optimise the efficiency of their trucks, ships, planes and drones and reduce maintenance and operational costs. While the uses of the IoT and sensor technology are only beginning to be explored, the benefits are already crystal clear.

4. Big data

Organisations collect and store all kinds of information about operations, customers, sales and more. This data is compiled from sources such as systems within the company, orders and shipment, logistics, weblogs for customer shopping patterns, mobile devices, GPS, sensors and social channels. Crunching through and making sense of all this information helps to deliver high levels of customer service, optimise marketing operations, generate predictive analytics to mitigate risk and prepare for future scenarios. Managing, analysing and visualising these mountains of data, however, requires advanced computing power and the application of sophisticated algorithms. Organisations with infrastructures capable of capturing, analysing and leveraging the data across their supply chains can make adjustments to inventories, capacities and pricing and make decisions – in real time – without missing any potential business opportunities. Big data enables them to optimise logistics, resulting in cost reductions, faster time-to-market and a smaller carbon footprint.

5. Digital networks, complete supply chain visibility and collaboration

Digital networks and exact location services – enabled by the IoT, GPS and big data – make it possible for everyone in the supply chain to track shipments in real time, whether it is the manufacturer, supplier, shipper or customer. Shipments are visible from when the order is placed to when the product reaches the delivery address. Digital networks enable each party in the supply chain to immediately identify and correct problems and make it possible to communicate an increase in demand for a product with relevant partners, enabling all stakeholders to address the issue by increasing supply or expediting shipping. Another benefit of digital networks and supply chain visibility is that processes between supply chain participants can be automated, speeding up transactions (ordering, invoicing and payments), reducing mistakes and significantly improving the performance of the entire chain.

Prepare to meet the challenges of the next ten years

The current supply chain is undergoing significant transformation and holds the promise of being completely self-managed in the not too distant future. The unprecedented pace of change will be driven by the five top disruptors discussed in this article, and embracing these radical technologies will prepare companies for the challenges of the next ten years, the rewards of which will be significant. It is no longer enough to simply invest in human resources, technology and infrastructure. Embracing, absorbing and applying these disruptors won’t be easy, but those who aren’t preparing to be part of this future are likely to remain in the past.

Share via: